Suprema compositio et munus positio latrinae ecclesialis

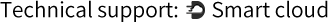

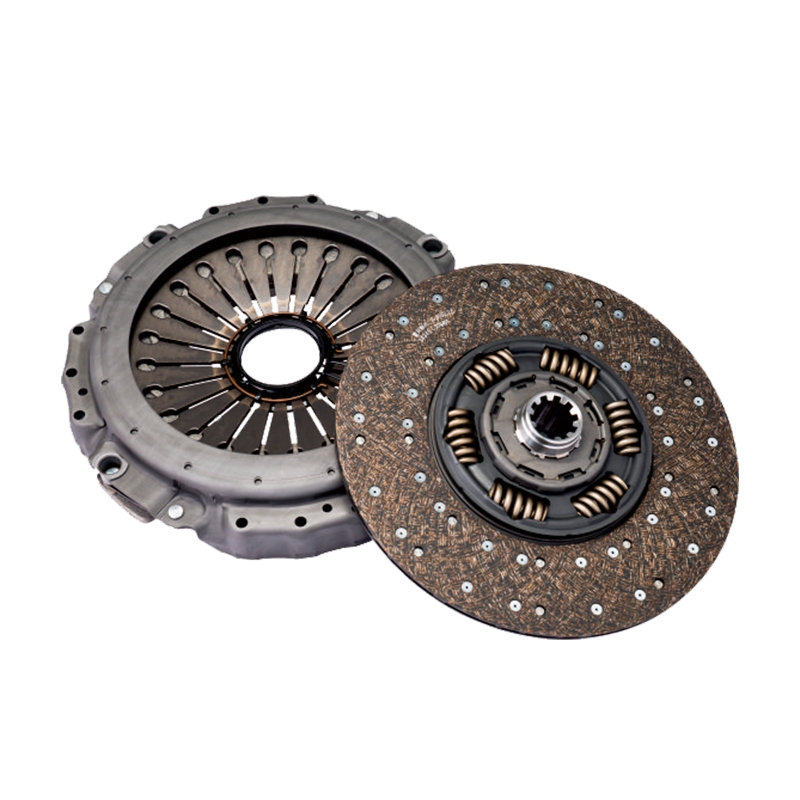

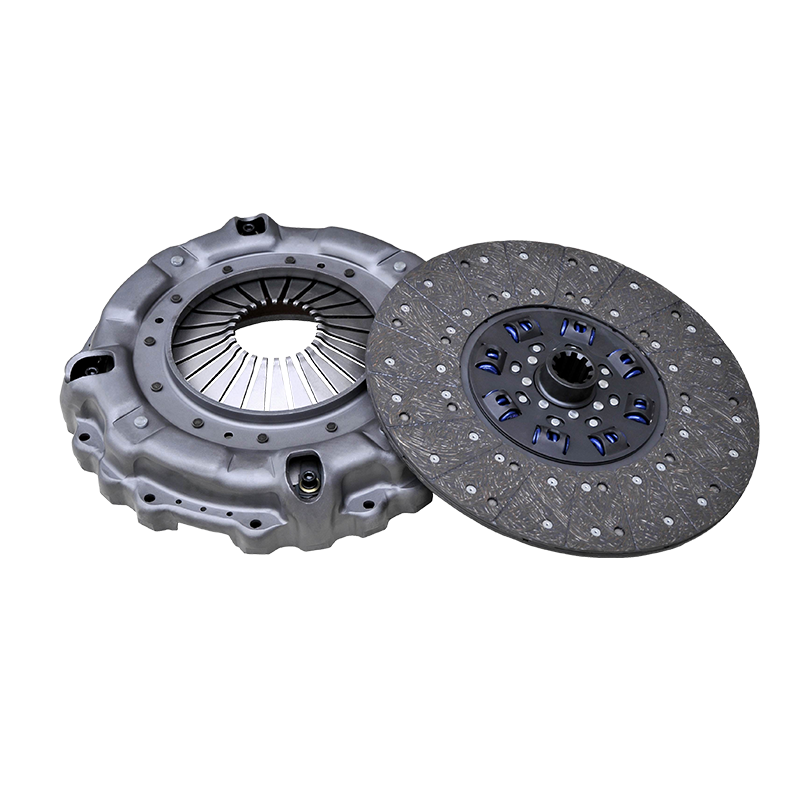

The gravibus officium salsissimus vir vivens lacessit discus conventus Est clavis transmissio componentis inter machinam et gearbox. Munus eius core est in proelio lenis consequi et plenam separationem potentiae. This assembly is composed of multiple components such as friction plate, driven disc hub, corrugated plate, pressure plate, etc. Among them, the friction plate is the contact component directly involved in power transmission and is the core hub of the entire system operation. When the engine is running, the clutch plate assembly controls the on and off of the power flow through the change of the contact state between the friction plate and the flywheel and the pressure plate, ensuring the smooth execution of vehicle starting, shifting, parking and other operations.

Core munus frictionis laminae in potentia tradenda

Core valor friction bracteae relucet in sua facultate ad vim potestatem accurate moderandam. In the power transmission stage, the pressure plate presses the friction plate against the flywheel surface under the action of the spring force. At this time, the friction plate transmits the torque output by the engine from the flywheel to the driven disc by virtue of its own friction with the metal surface, and then transmits it to the gearbox input shaft through the driven disc hub, and finally drives the wheels to rotate. In hoc processu, frictio coefficiens frictionis laminae directe determinat efficientiam tradendi potentiae. Solum cum frictio coefficientis stabilis et ampla est, transmissio Aureus sine lubrica et potentiae iactura vitari conservari potest. In the power cut-off stage, after the driver steps on the clutch pedal, the pressure plate separates from the friction plate, the friction between the friction plate and the flywheel disappears, and the power transmission path is interrupted, creating conditions for the shifting operation.

Directum impulsum friction laminae perficientur in ecclesiam laminam lacessit

Parametri attritionis laminae perficiendi sunt indices nuclei ad metiendam qualitatem gravem officiorum evulsio discorum conventus capiendi. Firmitas friction coefficientis clavis est. If the friction coefficient decreases significantly with the increase of temperature, it will cause the clutch to slip, the power transmission efficiency to drop sharply, and even cause problems such as the vehicle's inability to climb and slow acceleration. Resistentia gere decernit servitutis ecclesiam lamine defessa vita. Aliquet graves in statu operationis summi oneris diu sunt. Si lamella frictio nimis cito atterit, cyclus postea conventus minuetur et sumptus sustentationis augebitur. Ictum resistentiae frictionis lamellae etiam magni momenti est. Cum vehiculum acrius incipit vel accelerat, attritio bractea instantaneae incrementi in torques ictum sustinere debet. If its structural strength is insufficient, cracks or partial detachment may occur, directly leading to the failure of the clutch plate assembly. Materia delectu et processu tractationis lamellae attritae fundamentum est ad conservandum conventum laminae defessa.

Necessitudo inter attritionem laminam et vehiculum systematis transmissionis nexus

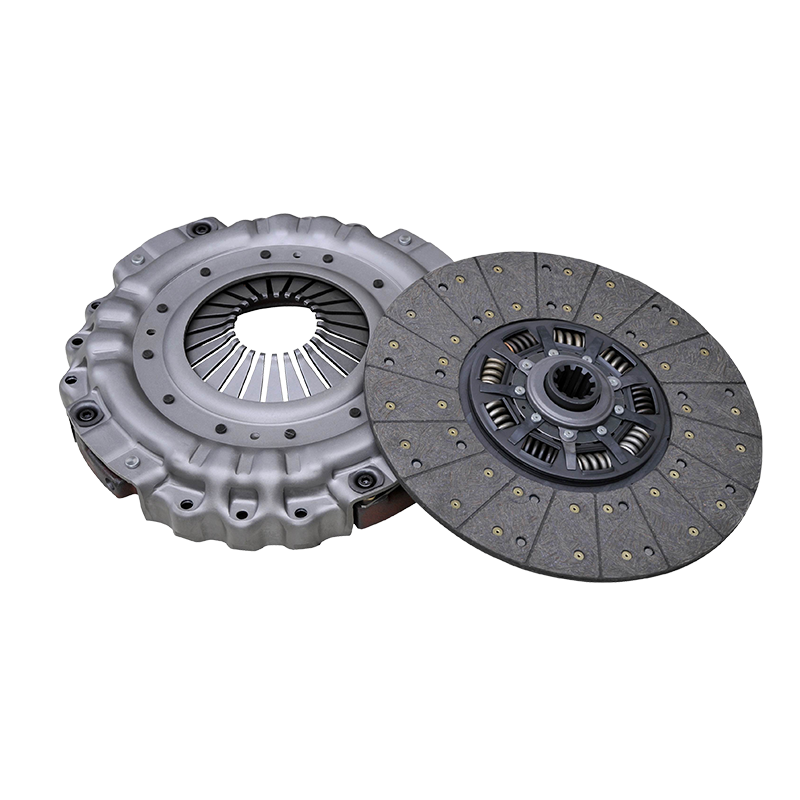

The performance of the friction plate is not only limited to the heavy duty truck clutch disc assembly, but also has a chain effect on the vehicle transmission system. Cum bractea frictio inaequaliter attrita vel attritio coefficientis fluctuat, ictum intermissus occurret in potestate transmissionis. Hic impetus ad axem posteriorem tradetur per gearbox, stipitem et alia componentia. Long-term accumulation may lead to increased gear meshing clearance, increased bearing wear, and even cause serious faults such as drive shaft resonance. On the contrary, high-quality friction plates can reduce the additional load of the transmission system through smooth power engagement, and extend the service life of key components such as the gearbox and drive axle. Ex prospectu vehiculi operationis, stabilitas attritionis lamella directe ad ratem auscultationem vehiculi refertur. Frequent clutch failures will cause the vehicle to stop, and reliable friction plate performance is the hidden prerequisite for ensuring transportation efficiency.

Materiae notae ac processus exigentias attritu laminis

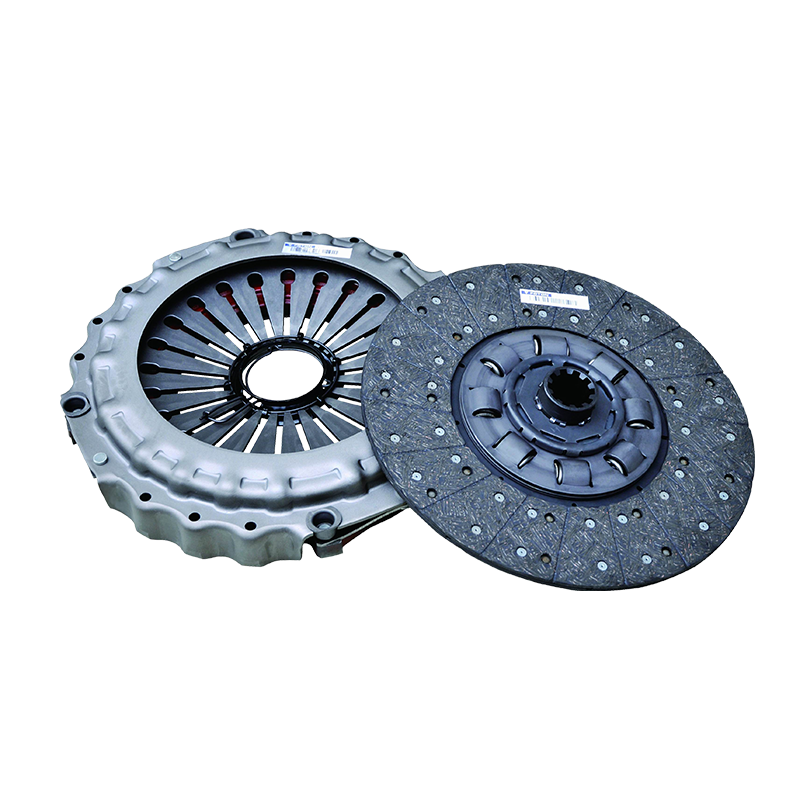

Effectus attritionis laminae ex materia compositione et processu fabricando determinatur. At present, mainstream friction plates are mostly made of composite fiber materials, with metal fibers, glass fibers, aramid fibers, etc. as the skeleton, mixed with friction performance regulators and high-temperature adhesives. This composite material can not only ensure a sufficient friction coefficient, but also maintain structural stability in high temperature environments. In processus fabricandis clavis uniformis fibrarum distributio est. Si densitas fibrarum localium insufficiens est, attritio bractea diversis velocitatibus induetur et vitae ministerium breviat. Curatio processus tenaces directe afficit summus temperatura resistentiae lamellae frictionis. Necesse est ut temperiem et pressionem pressius moderari, ut compages inter materias vires curet. Planities attritionis superficiei laminae etiam crucialis est. Too high roughness will aggravate the wear of the flywheel and the pressure plate, while too low roughness may lead to insufficient initial friction and affect the power transmission efficiency.

No.25, Hu Chuang via, Nova Districtus Industrial Park, Suzhou, Jiangsu, Sinis.

No.25, Hu Chuang via, Nova Districtus Industrial Park, Suzhou, Jiangsu, Sinis.  +86-13338663262

+86-13338663262